From the dream to the bicycle

1. Dream and idea

In the beginning there is the dream and the idea for a unique and individual bicycle. Make an

appointment for a personal consultation or just stop by.

In Morassi’s Open Workshop (hyperlink), all visitors can get an idea of the production in the

manufactory: How is a bicycle constructed and what techniques are used to turn a tube into a finished

bicycle frame?

2. Measuring

When it is clear where the journey is going, we start with a measurement of your body in our workshop.

These measurements serve as the base for bikefitting and provide the foundation for a perfectly fitted

and individualized bicycle.

3. Frame shape and usage profile

The next step is to determine where and how the bicycle will be used.

Especially in inner-city residential areas, bicycles are confronted with many challenges: high sidewalks

as a strain for wheels and frame, rails as urban tripping hazards and high traffic volume as an additional

obstacle through the urban jungle. On weekends, wild cross-country descents or even a trip to the

Black Sea in summer may be awaiting.

There are no limits to the ways in which bicycles can be used.

At Morassi, we take a close look at all the challenges that the bike will later face before building it, and

work with our customers to develop the ideal usage profile.

4. Planning

Once all wishes and dreams have been expressed, the planning of the bicycle frame begins. The focus

here is on the riding experience, comfort and demands on the frame: a perfectly fitted bicycle frame

makes the ride to the shops more comfortable. An individually ergonomically designed frame enables

better athletic performance.

What have you always wanted from your bicycle? At Morassi, we take all your wants and needs into

account during the design process.

5. Techniques and materials

The choice of material and technology greatly influences the handling and riding experience later on.

We combine modern design and the latest technologies with traditional frame building techniques like

„Fillet Brazing“.

What difference does it make whether a frame is made of Reynolds 531 or 853? Why might 921 be a

good idea as a chainstay? We involve you in the choice of materials and techniques as you wish and

give you comprehensive advice.

6. Design

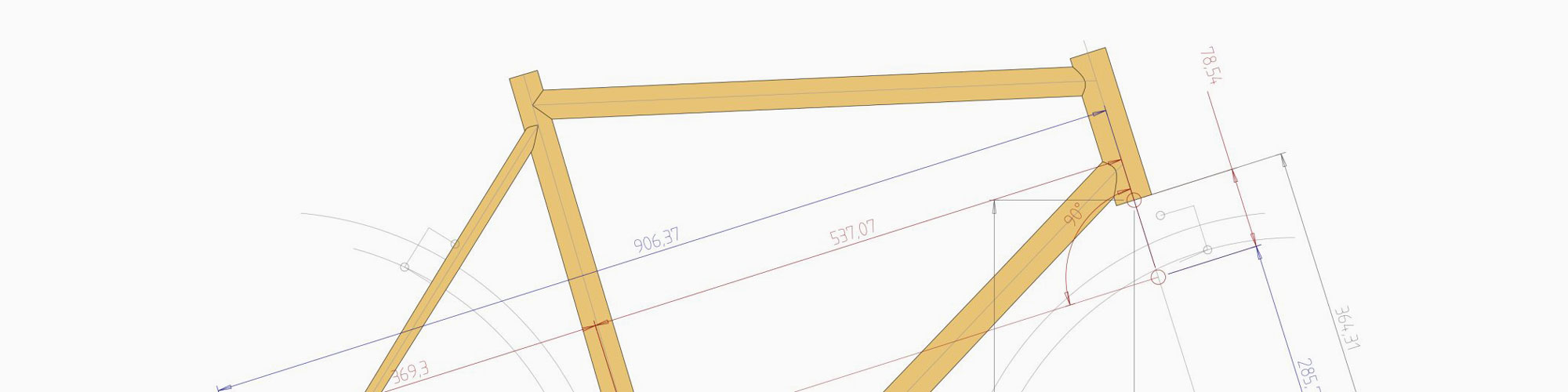

With this information we create the first draft of your dream bicycle. Here we work with international

industry standards such as BikeCAD and use renowned bike fitting systems.

7. Design elaboration and components

Based on the first draft, we work out the perfect components for your bicycle and file your wishes and

dreams into exact form. Hand-welded fork or carbon from China? Rohloff.de or Shimano XTR? What

are the advantages of gears in the bottom bracket, derailleur, hub gears? Can my bike have 5 cup

holders?

At Morassi we know the answers to any of your bicycle questions.

8. Handmade manufacturing

After every detail of the bicycle is planned, your frame will be handmade directly at our workshop in

Vienna Margareten. Depending on the order and complexity, it takes 2 to 4 weeks until you can

whoosh through the city on your dream bicycle.

9. Color design

We also pay attention to regionality and sustainability when it comes to color design. Our frames are

either painted or powder coated in Vienna. When it comes to color selection, we have the complete

RAL palette as well as many effect – and special coatings.

10. Construction

Once the frame is painted, the bicycle is assembled, and the details are fine-tuned for the perfect fit.

11. Enjoy !

Then it’s time to go! Get on, start pedaling and enjoy. Riding a handmade bicycle that is perfectly fitted

and bespoke to you and your body is an extraordinary feeling.